收藏

对比

编号 :

Diaphragm Powder Pump

- 产品描述

- 运行与安装

- 规格系列

- 解决方案

- 造型指导

- 资质

- 品牌介绍

-

- 商品名称: Diaphragm Powder Pump

- 商品编号: Diaphragm Powder Pump

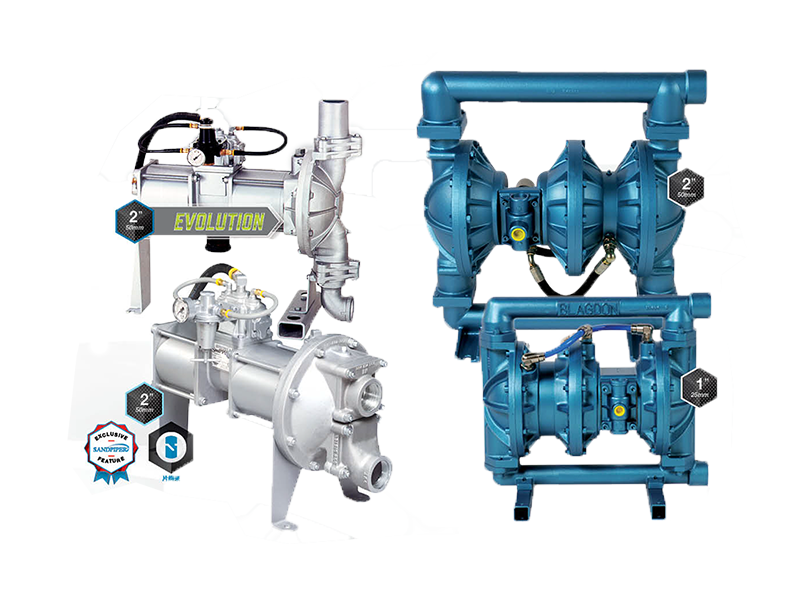

1. SANDPIPER Powder Pump:

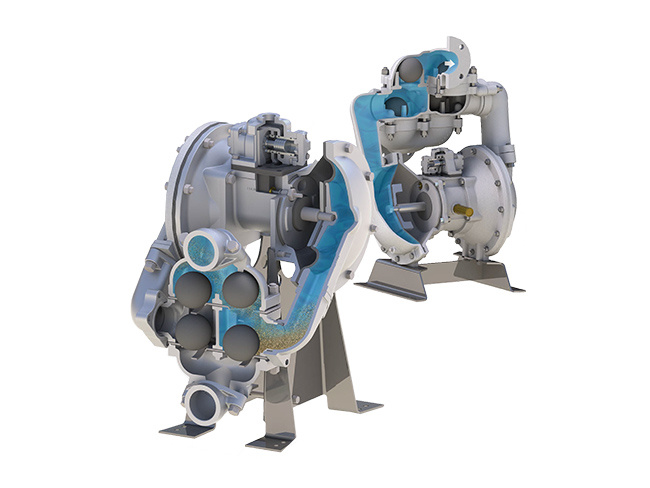

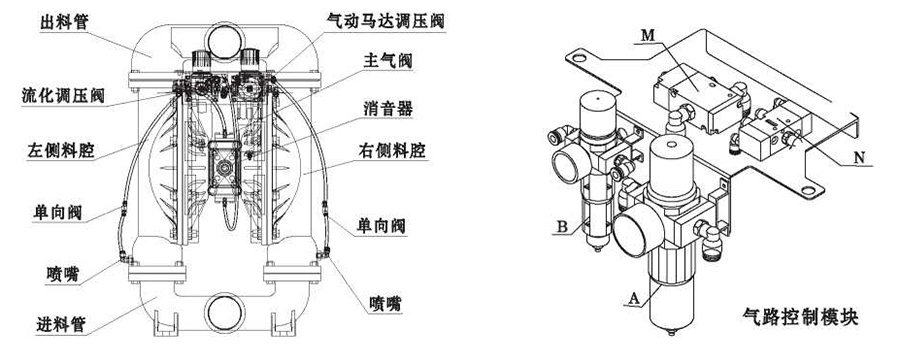

The SANDPIPER powder pump from the United States is a pump product used for transporting solid powder materials. The pump injects gas (air or nitrogen) at a certain pressure into the chamber during each discharge stroke, keeping the solid powder in a semi-fluid state. Driven by the diaphragm, the powder mixed with gas is expelled from the chamber and transported over a short distance through pipes.

The SANDPIPER powder pump adopts a new gas path induction distribution technology, achieving separation of the pneumatic motor's gas supply and the powder fluidization gas path. The fluidization gas pressure can be set according to the flowability of the powder (1.5-5.5 bar). For powders with low bulk density and good flowability, a lower fluidization gas pressure can be set to save energy and reduce the load on the air release component. The pneumatic motor's gas supply pressure can be set according to the delivery volume (2.0-3.8 bar).

The SANDPIPER powder pump is currently one of the products with relatively low energy consumption in its category, mainly due to its advanced main valve design and precision manufacturing process. The SANDPIPER team continuously optimizes and innovates to meet various application needs, combined with world-class professional design advantages, allowing our products to meet more application fields. The use of this product has certain requirements for the powder and the conveying process, and we cannot apply it blindly. In addition to existing mature application processes, other suggestions should be consulted with our technical department, and the material performance survey form should be filled out carefully. If conditions permit, we also welcome material testing. We are equipped with complete experimental facilities. Over the past decade, we have accumulated a lot of application data and experience.

2. Features and Applications:

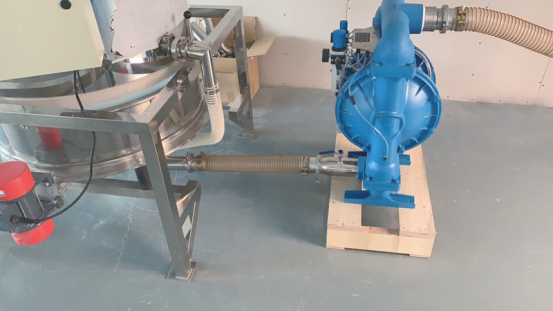

a. Extremely convenient installation, compact size, the pump's discharge port can be connected to the inlet of other equipment with a flexible hose (or a rigid pipe). The pump's feed port can self-suction powder, outputting in a slightly positive pressure state, entering a closed device, with a small amount of gas discharged through the air release component;

b. Avoids dust flying around the production workshop, reducing air pollution and raw material waste;

c. Powder materials are transported in a closed management system, minimizing contact between operators and the powder;

d. The system is economical, simple to install and use, unlike expensive traditional large and complex pneumatic and mechanical conveying systems;

e. Lightweight, can be easily moved and used anywhere (can be installed on a small cart). Ready to use, no installation or debugging required;

f. Speed is adjustable. The pump's operating frequency can be adjusted by the intake pressure to meet the powder addition requirements of different sections;

g. The newly developed flap valve powder pump can transport powders with slight fibers or small solid particles.4. Product Structure:

5. Specifications and Models:

Flap Valve Pump

2Inch Aluminum Alloy Model:HDF20A

2Inch Stainless Steel Model:HDF20S

3Inch Aluminum Alloy Model:HDF30A

3Inch Stainless Steel Model:HDF30S

6. Application Fields:

a. Powder Types:

Aerosil, precipitated silica, hot melt adhesive resin, light calcium carbonate, nano-active calcium carbonate, talcum powder, aluminum hydroxide, mica powder, expanded perlite, diatomaceous earth, starch, flour, flame retardants, etc.

b. Application Industries:

High-temperature adhesives, room temperature adhesives, grout, liquid adhesives, thermal insulation materials, some battery anode and cathode materials, nano new materials, daily chemicals, pharmaceuticals (raw material intermediates), etc.

7. Technical Parameters:

Specifications

Pneumatic Motor (Compressed Air)

Separate Fluidization Gas (Compressed Air or Chlorine)

Conveying Capacity Kg/h

Conveying Height m

Continuous Gas Flow m'/min

Working Pressure bar

Gas Consumption m'/min

Working Pressure bar

Kilograms/Hour

Meters

L5Inch Pump

0.6

1.5-3.8

0.3-0.4

1.8~5.0 bar

100-2000

0~30

2Inch Pump

0.9

1.5-3.8

0.4-0.5

1.8~6.2bar

250-4000

0~40

3Inch Pump

1.5

1.5-3.8

0.4-0.5

1.8~6.2bar

400-6000

0~40

Note:The parameters in the above table are the actual values obtained from laboratory tests and customer site applications of various powders conducted by our company, for reference only!

Parameter Explanation:

The conveying capacity and height of the powder pump mainly depend on the type, particle size, and flowability of the powder. Additionally, the installation method of the pipeline and the supporting auxiliary equipment also have a significant impact, so there can be considerable differences in conveying capacity. For reasonable selection, it is recommended that customers carefully fill out the product catalog page "Material Properties Survey Form"; if possible, it is best to send materials to our company for testing.78. Application Cases

8、应用案例

客服热线

关注我们

公众号

关注公众号 获取更多灵感

- 返回顶部